Understanding the Two Main Types of Concrete Plants

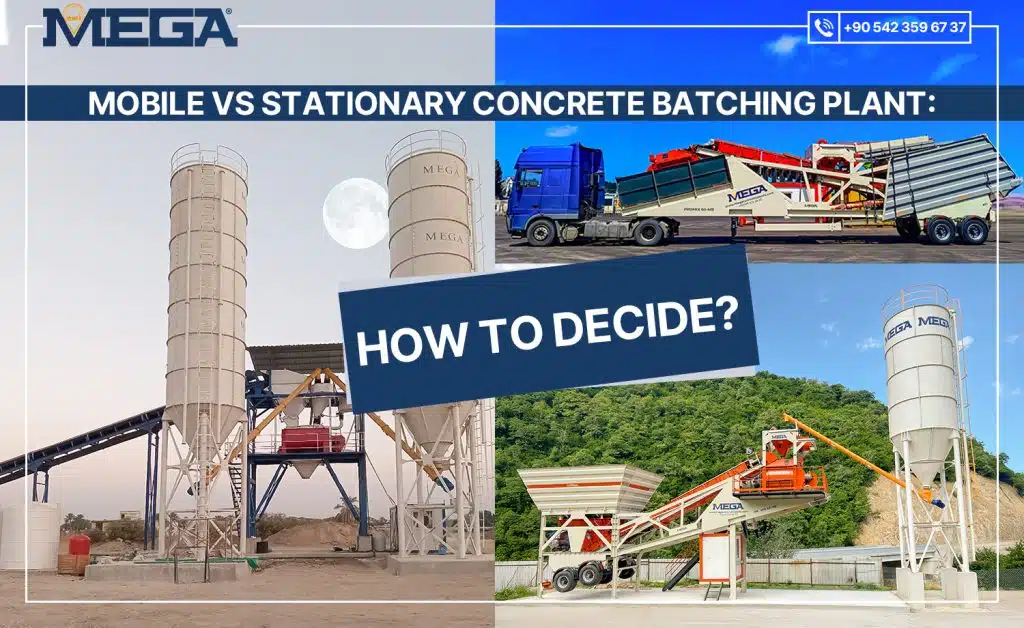

In general, batching plants are divided into two categories – stationary (fixed) concrete plants and mobile (portable) concrete plants. Concrete production is a critical part of any construction project, and having the right concrete batching plant can make or break your project’s schedule and costs.

Comparison Between Mobile and Stationary Concrete Plants

Stationary plants are large, permanent installations used for long-term, high-volume work, while mobile plants are compact units mounted on chassis or trailers for flexibility. Understanding the key differences – including production capacity, setup time, mobility, cost, and site conditions – will help project engineers and buyers select the right type.

Stationary Concrete Plant Characteristics and Advantages

Stationary concrete batching plants are large, fixed installations often built on permanent foundations. These plants can produce very high volumes of concrete continuously, making them ideal for large-scale construction and infrastructure projects.

A stationary plant typically consists of silos, hoppers, conveyor belts, and mixers that are permanently installed on site.

Because they are built on concrete foundations, stationary plants are stable and efficient, with lower failure rates and long service lives.

In practice, stationary plants are chosen when a high concrete output (often dozens or even hundreds of cubic meters per hour) is needed for an extended period. For example, a large residential complex, bridge, or highway project under construction over many months or years usually relies on a stationary plant to ensure a continuous concrete supply.

Why Mobile Concrete Plants Offer Speed and Portability

In contrast, mobile concrete batching plants are designed for flexibility and speed. A mobile plant is a compact, trailer-mounted unit that can be quickly set up and taken down as needed. These plants typically include all the same functions (storage, weighing, mixing, discharge) on a single movable frame.

A key benefit of a mobile plant is that it can be relocated from site to site.

This makes it ideal for short-term projects or construction in remote areas where building a stationary concrete batching plant isn’t practical. For example, road crews building a highway segment or tunnel over a few months can tow a mobile batching plant to each new section, rather than transporting concrete from a distant central plant. Mobile plants also have smaller footprints and often come pre-wired, so they require much less installation time – sometimes 50% faster than a stationary plant. Typical mobile units range from about 30 to 120 m³/hour.

Production Capacity and Project Suitability of Concrete Plants

Choosing a Concrete Plant Based on Project Volume

One of the first factors to consider is production capacity. If your project requires very large volumes of concrete every day, a stationary plant will usually be the better choice. Modern stationary plants can produce hundreds of cubic meters per hour.

These plants can even use multiple mixers simultaneously to meet mega-project demands. The higher output is due to a larger mixer size, higher-power motors, and the ability to install large silos and conveyors. Also, stationary plants can be customized with big cement silos (50–100 tons or more) and heavy-duty aggregates conveyors, which further boosts continuous production.

This makes stationary plants suitable for long-term, high-volume works like industrial developments, large housing complexes, or infrastructure projects that run for a year or more.

By contrast, mobile plants cover a wide range of smaller capacities. Many mobile plants handle up to about 60–100 m³/h. Advanced mobile designs (with two chassis trailers) may reach over 120 m³/h, which is sufficient for fairly large projects if needed.

However, the general rule is: if your project’s total concrete demand is moderate and you only need a plant for a short time, a mobile batching plant can often meet the need.

Mobile plants are suitable for projects with a short construction period and little demand for concrete.

Concrete Plant Installation Time and Setup Costs

Concrete Plant Setup: What to Expect for Each Type

Another crucial difference is installation time. Because stationary plants are fixed installations, they require significant site preparation. You usually need to pour concrete foundations, erect towers, install conveyors, and wire the control systems. This setup can take weeks or months and may require cranes and specialized technicians.

Mobile plants come pre-wired and mounted on transport frames, so they have “50 percent less” installation time than stationary plants. In practice, a mobile plant can often be set up on a level pad in a few days. This fast setup is a major advantage on projects where time is tight or where you cannot afford to wait for a permanent plant.

Concrete Plant Foundation Requirements

Likewise, mobile plants typically have lower installation costs. Because they are compact and require little to no special foundation, you avoid the expense of concrete pads and heavy earthworks. Mobile batching plants require less space and eliminate costs for laying down a concrete foundation. The ability to simply park a mobile unit on a flat area and hook it up can save both time and money.

For a temporary or short-term project, these savings can be significant. On the other hand, a stationary plant’s installation is justified only if you will use the plant long enough to amortize that investment. If your project is months long, the one-time setup cost can be spread out over the project’s life. If the project is only weeks long, a stationary plant’s heavy setup may not be worthwhile.

Mobility and Flexibility in Concrete Plant Usage

Concrete Plant Mobility for Multi-Site Operations

The mobility of the plant is a practical consideration. Mobile batching plants are specifically designed to move. They often have built-in wheels or are mounted on trailers, so they can be towed by trucks. If your project involves multiple sites or if you anticipate relocating the plant at some point, a mobile plant offers great flexibility.

For example, road or bridge work that moves along a highway corridor benefits from a mobile setup: the plant can be transported to each new section, keeping the concrete source close by. Mobile plants also allow you to produce concrete on-site, saving the cost and time of hauling ready-mix from far away. In fact, the biggest benefit of a mobile plant is making concrete right at the construction site, which saves a lot of time and labor cost compared to a fixed plant.

Space and Terrain Considerations for Concrete Plants

Stationary plants, by contrast, are not meant to be moved. They typically sit in one place for the life of the project. Their fixed position can be an advantage if you have a single large site and want a solid, stable production base.

But it means that once built, the plant cannot easily be shifted to another site or project. This rigidity also means you must plan carefully for site conditions: the ground must support the heavy foundation, and access roads must handle delivery trucks.

If your site is confined or has limited space, a compact or mobile plant is preferable. Modern mobile/compact plants are engineered to fit into tight areas, with designs that can adapt to narrow spaces and still deliver high performance.

Cost Analysis: Mobile vs. Stationary Concrete Plant

Budgeting for a Concrete Plant: Initial and Operating Costs

Budget is always a key concern. In general, stationary plants have higher upfront costs than mobile plants. This is due to their larger size, the heavy structures (foundations, silos, conveyors), and often more advanced automation systems.

Buyers should expect to pay more for a high-capacity fixed plant, especially if custom features or additional automation are included. However, the long-term value of a stationary plant can be greater if you need it continuously.

Mobile plants usually cost less initially, making them attractive for smaller budgets or shorter projects. Moreover, operating costs can be lower if mobile plants use less power or have simpler controls.

Operational Costs of Running a Concrete Plant

Operational costs should also be factored in. Stationary plants might use electricity or have large engines that consume diesel continuously, whereas some mobile plants have smaller, fuel-efficient engines. If fuel or power is expensive on your site, look at the energy efficiency of the plant.

Likewise, labor and maintenance matter: stationary plants may need a full-time technician for the control system, while a mobile plant often operates more simply.

Making the Right Concrete Plant Choice for Your Project

Concrete Plant Selection Based on Site Constraints

Choosing the right concrete plant is all about matching the plant’s strengths to your project’s needs. Here are some practical guidelines:

- Project Duration – If your project is short-term or likely to move locations, lean toward a mobile batching plant. If it’s long-term (months or years in one place), a stationary plant is worthwhile.

- Production Demand – Estimate how much concrete you need per day and per week. For high daily volumes, a stationary plant may be the only way to keep up. For modest volumes, a mobile plant can suffice.

- Mobility Needs – Do you need to relocate the plant during the project? Will you rent or re-use the plant on future projects? Mobile plants win if you need portability; stationary plants are one-and-done.

- Site Constraints – Assess your site’s space, access, and ground conditions. If space is tight or you can’t pour heavy foundations, a mobile/compact plant is often easier to accommodate.

- Budget – Compare initial and operating costs. Consider both the price of the equipment and the installation/operational expenses. Remember that higher-capacity stationary plants cost more upfront but may be cheaper per unit of concrete when fully utilized.

- Quality and Automation – If your project demands very precise mix control and consistency, some stationary plants offer advanced controls and mixers (e.g. double-shaft mixers). Mobile concrete plants also include SCADA systems like stationary plants.

- Infrastructure – Stationary plants may require connections to mains power, water, and even permanent transportation infrastructure (roads, conveyors). Mobile plants often have self-contained systems for power and water, useful on remote sites.

- Future Use – If you or your company plan to use the plant on multiple jobs, consider resale or rental value. Mobile plants can often be sold or moved easily to a new job, whereas a stationary plant is usually a fixed asset for a specific location.

Conclusion: Choosing the Best Concrete Plant for Your Needs

By carefully evaluating these factors – use case, production needs, installation and mobility, and costs – you can guide your decision on which concrete plant is right for your project. In many cases, consulting with equipment suppliers can also help; they often share insights on the typical use cases for each model. Ultimately, the right plant is the one that meets your project’s requirements without over-investing in unnecessary capacity or flexibility.

CONTACT US FOR EXPERT GUIDANCE ON YOUR PROJECT — WHERE 25 YEARS OF EXPERIENCE MEETS INNOVATION.

90m3 Concrete Batching Plant For Sale

100 m³/h Mobile Concrete Plant For Sale

Written by Kadir MERSINLI

+90 542 359 67 37